Buyer’s Checklist: Aluminum Gantry Crane Specs Guide

Buyer's Checklist: Specifications to Confirm Before Ordering an Aluminum Gantry Crane

Aluminum gantry cranes are lightweight, portable, and flexible lifting solutions used in workshops, laboratories, construction sites, and maintenance operations. Unlike traditional steel cranes, they are easy to transport, assemble, and adjust, making them ideal for temporary setups or small spaces.

However, choosing the right crane requires more than just picking a model with a rated load. Confirming key specifications beforehand helps avoid inefficiencies, safety hazards, or unnecessary costs. This guide provides a practical checklist for buyers to select the aluminum gantry crane that best suits their needs. Learn more on the detailed crane specifications of hot sale 6 types of Aluminum Gantry Cranes and tailored lightweighted gantry crane are provided to get your tailored solution by leaving a message downblow or by WhatsApp: +86 151 3871 1597.

Load Capacity

Load capacity is the most critical specification. Lifting a load heavier than the crane's rating can cause structural damage or accidents. Always include a safety margin of 20–30% above the heaviest anticipated load.

Typical Load Capacities of Portable Aluminum Gantry Cranes

| Crane Model | Rated Load (ton) | Recommended Use |

|---|---|---|

| Small Gantry | 0.5 | Light parts, lab equipment, or small machinery |

| Light Duty | 1 | Workshop maintenance, electroplating, cleanroom tasks |

| Medium Duty | 2 | General on-site lifting, field service tasks |

| Heavy Light-Duty | 3 | Heavier machinery parts, maintenance, or small construction loads |

Tip: Consider peak loads and future requirements. It's better to slightly over-specify than to risk overloading.

Lifting Height

Lifting height depends on your operational environment. Indoor workshops with low ceilings and outdoor sites have different requirements. Adjustable height models allow flexibility for multiple tasks.

| Parameter | Recommendation |

|---|---|

| Maximum Height | Ensure the crane can reach the highest point needed (typically 2,000–4,000 mm) |

| Adjustable Height | Recommended for varied tasks or multiple workstations |

| Minimum Height | Should provide stable lifting at low levels without compromising safety |

Tip: If your operations involve stacking or shelving, consider models with higher lifting ranges and quick height adjustment pins.

Span / Beam Width

The crane span determines the distance between the legs, which affects stability and workspace compatibility. Some models offer adjustable spans to accommodate different load sizes or workshop layouts.

| Parameter | Recommendation |

|---|---|

| Fixed Span | Good for repetitive lifts in consistent layouts |

| Adjustable Span | Ideal for flexible workflows and varying load sizes |

| Maximum Span | Make sure it fits within aisle widths, storage areas, or vehicle access points |

Tip: Measure your workspace carefully. A crane too wide may be difficult to maneuver; too narrow could limit lifting operations.

Portability & Folding Features

One of the key advantages of aluminum gantry cranes is portability. Foldable legs, lightweight aluminum construction, and casters allow the crane to be moved easily between sites.

Portability Checklist:

- Foldable Legs: Collapse inward to reduce storage footprint. Makes transportation in vans or trailers easier.

- Weight: Lightweight aluminum alloy allows safe handling by two or more people without heavy machinery.

- Casters: Heavy-duty swivel or brake casters provide smooth movement on concrete, tile, or workshop floors.

- Assembly Time: Choose cranes with quick folding and unfolding mechanisms for faster on-site deployment.

Tip: Keep caster wheels clean and lightly lubricated to maintain mobility and avoid scratching floors.

Material & Construction

Material quality ensures safety and durability. Aluminum cranes are naturally corrosion-resistant, but thickness, welding, and finish play a big role in long-term performance.

| Feature | What to Look For |

|---|---|

| Aluminum Alloy | High-strength, lightweight, corrosion-resistant |

| Welding Quality | Seamless, reinforced, free of gaps |

| Beam Thickness | Supports rated load without bending or deflection |

| Surface Finish | Anodized, painted, or powder-coated for protection in humid or outdoor environments |

Tip: Inspect joints, welds, and beam surfaces before ordering, especially for foldable or adjustable cranes.

Trolley & Hoist Options

Most aluminum gantry cranes include trolleys or are compatible with hoists. These allow horizontal movement of loads along the beam.

- Manual Trolley: Simple, cost-effective, suitable for light and medium loads.

- Electric Trolley/Hoist: Optional for repetitive lifts or heavier loads; increases productivity.

- Attachment Points: Ensure the trolley or hoist aligns with the beam and your load lifting plan.

Tip: Check trolley wheel type and track compatibility to prevent uneven wear and operational problems.

Customization Options

Every operation has unique requirements. Many suppliers offer optional customizations:

- Adjustable span or lifting height for unusual workspace dimensions.

- Foldable leg designs for compact transport or storage in tight spaces.

- Paint and finish options for visibility or environmental protection.

- Manual or electric hoist configurations for specific lifting needs.

Tip: Planning customization at the order stage saves time and ensures the crane matches your workflow perfectly.

Safety & Compliance

Safety is non-negotiable. Ensure the crane meets local safety standards and includes features to protect both operators and equipment.

| Safety Feature | Why It Matters |

|---|---|

| Rated Load Markings | Prevents accidental overload |

| Stability Design | Anti-tip features ensure secure lifting |

| Accessibility for Inspection | Easy access to bolts, welds, and moving parts |

| Maintenance Requirements | Low maintenance keeps the crane operational and safe |

Tip: Regularly inspect all moving parts and structural components, especially after transport.

Budget & Price Considerations

Price varies depending on load capacity, adjustability, portability, and customization. While entry-level fixed cranes are more affordable, adjustable and foldable cranes often provide better long-term value.

| Crane Type | Typical Price Range | Notes |

|---|---|---|

| Fixed Height aluminum gantry crane | Low | Simple, entry-level, limited flexibility |

| Adjustable height aluminum gantry crane | Mid | Allows varied lifting heights, ideal for multiple tasks |

| Adjustable height & span aluminum gantry crane | Higher | Maximum flexibility for workshops with changing layouts |

| Foldable aluminum gantry crane | Mid-High | Portable, ideal for mobile or temporary operations |

Tip: Compare cost versus operational benefits. A slightly higher upfront cost may save time and increase productivity.

Conclusion

Selecting the right aluminum gantry crane requires careful planning. Confirming load capacity, height, span, portability, material, trolley options, safety, and budget ensures you get a crane suited to your workflow.

A proper checklist avoids costly mistakes, improves on-site efficiency, and extends crane life. Always communicate your detailed requirements to the supplier for a tailored quotation that meets your operational and safety needs.

Tip: Keep this checklist handy whenever you evaluate new cranes, and review it periodically if your operations expand or change.

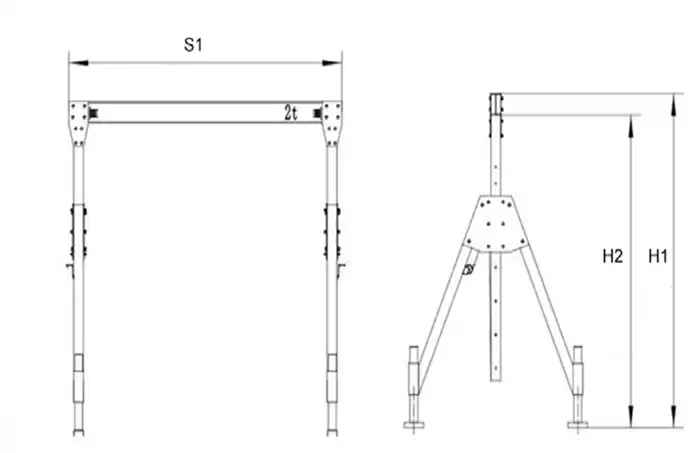

Crane capacity: 1 ton to 10 ton, S1- crane span, and H2 crane lifting height , all can be tailored as per your specifications

FAQ – Aluminum Gantry Crane Buyer's Guide

1. What load capacity do I need for my aluminum gantry crane?

Choosing the right load capacity is crucial. Consider your heaviest lift plus a 20–30% safety margin. Light-duty cranes usually handle 0.5–1 ton, medium-duty 2 tons, and heavier light-duty models 3 tons. Always check whether the crane's rated load matches your workshop or on-site lifting requirements.

2. How do I know which lifting height is suitable?

Measure your workspace and any shelving, equipment, or storage areas. If you need to lift to multiple heights, an adjustable-height model is best. Typical portable aluminum gantry cranes offer heights from 2,000–4,000 mm, with pins or quick-connect systems for easy adjustment.

3. Should I choose a fixed or adjustable span crane?

It depends on your workflow. Fixed-span cranes work well for repetitive lifts in consistent layouts, while adjustable-span cranes provide flexibility for different load sizes or changing workshop layouts. Always check your aisle width and space constraints before selecting.

4. How portable are foldable aluminum gantry cranes?

Foldable cranes are designed for quick transport and easy storage. Collapse the legs inward, move the frame on heavy-duty swivel or brake casters, and lift in small sections if needed. Lightweight aluminum makes it feasible for two operators to handle safely without heavy machinery.

5. What should I look for in material and construction?

Check for high-strength aluminum alloy, seamless welding, and reinforced beams. Proper finishing (anodized or powder-coated) protects against corrosion. This ensures long-lasting performance even in humid or outdoor environments.

6. Can I use a manual or electric trolley with the crane?

Yes. Manual trolleys are cost-effective for light to medium loads, while electric hoists are suitable for repetitive lifts or heavier loads. Verify the trolley fits the beam and aligns with your load movement plan for smooth operations.

7. Are there customization options available?

Many suppliers offer adjustable spans, lifting heights, foldable legs, surface finishes, and hoist configurations. Customization ensures the crane fits your workflow, storage space, and safety requirements.

8. How do I ensure safety when using a portable aluminum gantry crane?

Always confirm the rated load, inspect welds and bolts, and ensure the crane is stable. Use casters properly, and train operators on folding, unfolding, and adjustment procedures. Periodic maintenance is key, especially after transport.

9. How do price differences affect my choice?

Fixed cranes are usually more affordable but offer limited flexibility. Adjustable and foldable cranes cost more upfront but increase operational flexibility, reduce setup time, and improve productivity, making them cost-effective over time.